Best Windshield Repair Kits

by ASTM and ANSI Auto Glass Standard Lab Tests

Click Here to Buy The Product

Home / WINDSHEILD REPAIR KITS LAB TEST SCORES

The windshield is the third most important safety device in a vehicle. There are 4 Federal Motor Vehicle Safety Standards involving the windshield and there is an ANSI Auto Glass Industry Standard for Windshield Repair Kits.

REPORT

It has been Ruled in Federal Court in Ultra Bond v Safelite, that; " No matter how well trained the technician is or how high the customer satisfaction rating is, it does not prove that the windshield repair is safe or can pass the ROLAGS Tests."

Using science and the windshield repair industry recognized lab test scores to find the best windshield repair kit on the market is the safest option for you and your customers.

Since 1994 it was recommended in the United States Windshield Repair Guidelines that those that manufacture or sell windshield repair kits and windshield repair resins pass the same test as a new windshield, that being (1) Federal Motor Vehicle Safety Standard (FMVSS 205) tests required of a new windshield along with the same (2) Standard Test Method for Strength of Glass by Flexor, ASTM C158 used by all glass manufacturers to test all glass products which includes windshield glass (float glass) and laminated glass. This will compare the Repaired Safety/Laminated/Windshield Glass Strength to that of New Safety/Laminated/Windshield Glass Strength. That test is called the Mechanical Strength by 3-Point or 4-Point Bend. This is the one and only test that can determine the efficacy of a windshield repair system's, tool, methods, resin and curing. It is the only test that can compare and separate for weaknesses in any individual part of the repair system which includes the six parts of a windshield repair system, that being the: (1) Tool holding structure or bridge, (2) Tool injector (3) resin, (4) methods to fill, (5) curing method, and (6) curing light.

In 2007 and 2014 The United States Auto Glass Industry put forth a new American National Standards Institute (ANSI) approved Windshield Repair Standard named the Repair of Laminated Auto Glass Standard (ROLAGS). This industry standard also called for windshield repair kit manufacturers to lab test their mechanical strength by 3-point bend as it compares to New Laminated Glass so as to show the restoration properties of their repair system as it compares it the same test used by glass manufactures for all windshield glass and laminated glass. To date no company other than Ultra Bond has disclosed those test results. Therefore, we decided to test and disclose those test scores for you. We welcome a challenge by the others to these test results. We used two tests from the Industry Standard for this report, Resistance to Thermal Cycling followed by Mechanical Strength by 3-Point Bend Test. The 3-Point Bend Test measures (1) Tension, (2) Compression (3) Adhesion (4) Modulus of Rupture and (5) Shear all in one test. Theses (two) tests discloses the DNA of a Windshield Repair.

In the future if those selling professional windshield repair kits or do-it-yourself windshield repair kits disclose their kit's mechanical flexural bend strength tests numbers per the 3-Point Bend Test then they can send us verifiable lab test results and we will report those results in this report. If they do not have the resources to test on their own, they are welcome to use our lab.

FREE TESTING FOR YOU- If you are currently a windshield repair technician and do not have the industry recommended lab tests on your repairs, we will do the test for you for FREE. Call or email Rich for details; (970) 216-8156; email - rich@ultrabond.com

This is the DNA of a Windshield Repair,

Mechanical Strength by the 3-Point Bend Test

Compared to New Laminated Auto Glass Strength

How to Read the Graph of the Lab Test Report

The Graph Tells the Story.

- The numbers on the left are the load measurement in Newtons.

- The bottom numbers are the time of failure in seconds.

- The first dip in the graph is when the repair failed and that is the score of the repair.

- The second dip is when the other layer of glass failed or broke.

Below are the Lab Report Graphs of Undamaged Windshield/Safety Glass Compared to Safety Glass with a Crack or Chip called a Star-Break.

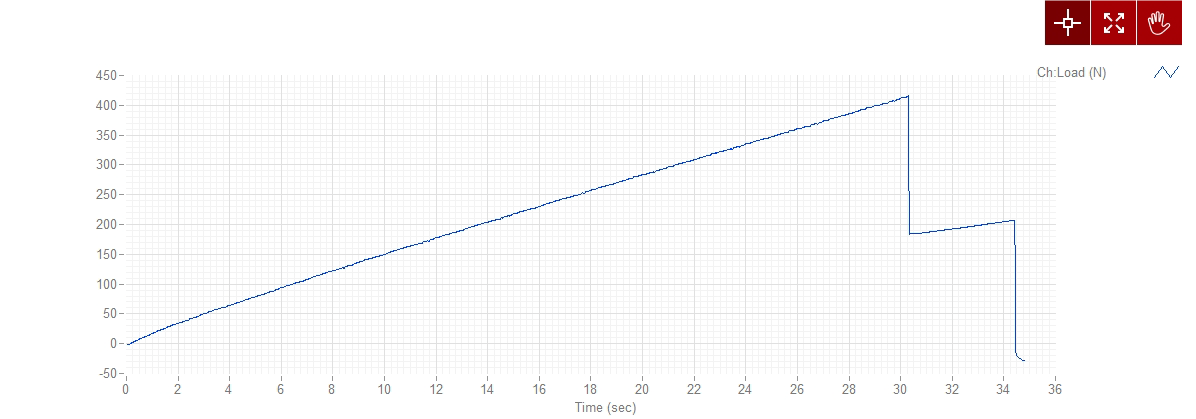

Breakage Graph of New

Undamaged Windshield Glass

This graph shows how undamaged laminated windshield safety glass breaks. It will usually show both layers breaking at the same time or one layer breaking first with the second layer close behind it. In this sample both layers broke simultaneously at 561 Newtons with a time of failure of 41 seconds.

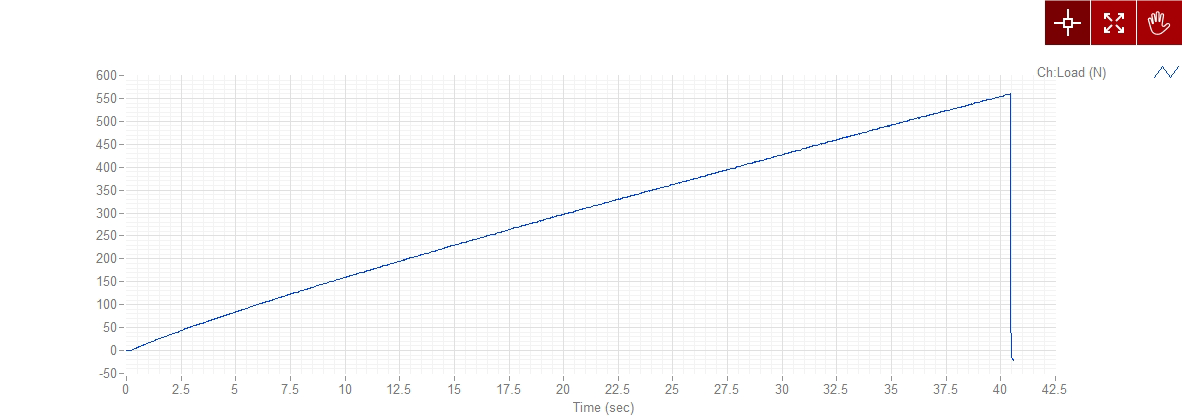

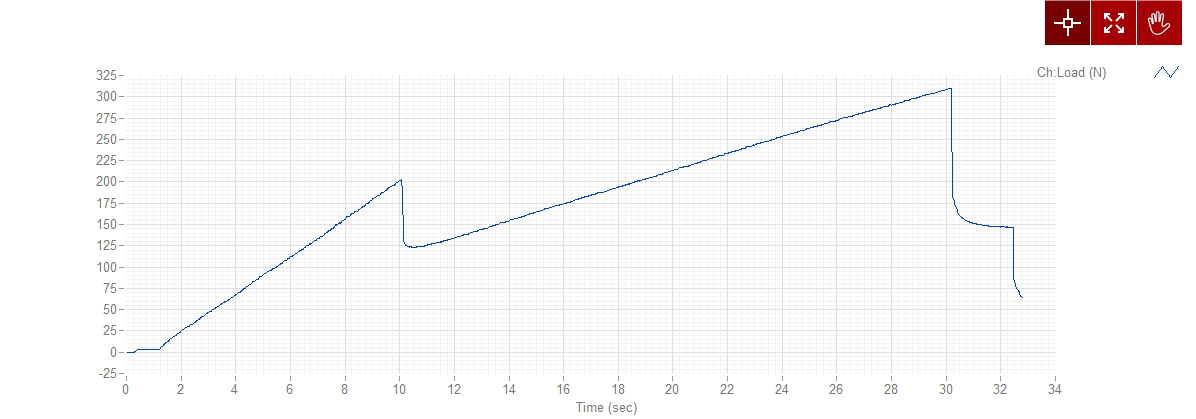

Breakage Graph of Windshield Glass with the Common Star-Break Chip

This graph shows what an unrepaired chip does to safety glass. A Severe loss of strength, altered break-pattern and decrease in time of failure. The first layer failed at 200 Newtons in 10 seconds, the second layer failed at 310 Newtons at 30 seconds. This in a head-on crash, rollover or an object or debris hitting the windshield could make the difference on whether there would be injuries or death as well as compromising the airbag crash-pulse and its function as the airbag backboard.

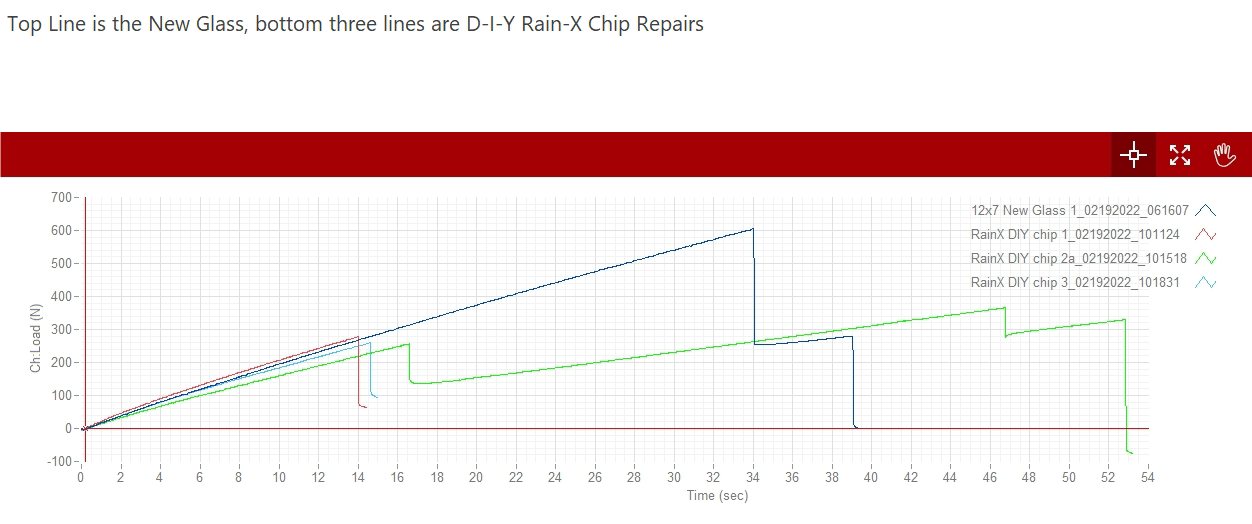

Lab Report Graph of an Inferior Windshield Chip Repair

In this Graph the new laminated glass is the top line. The other three below the new glass line are the three repairs. This graph shows the repair restored only 43% of New Laminated Glass Strength; did not restored the Break-Pattern and reduced the Time of Failure.

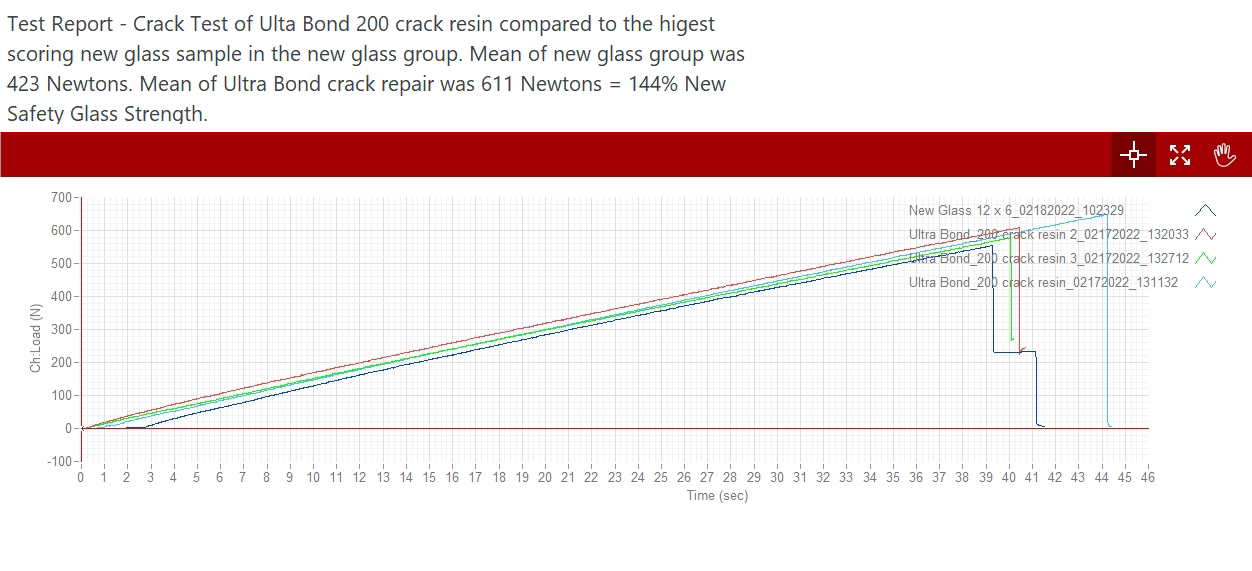

Lab Report Graph of a Superior Windshield Crack Repair

In this Graph the new glass is the line on the bottom. The other three on top are the three repairs. This graph shows the repair restored over 100% of Strength, restored the Break-Pattern and extended the Time of Failure. Most important was Consistency, which means low standard deviation.

#1 136%

Ultra Bond Wonder Bar Windshield Repair Kit

Test Components:

- Ultra Bond Wonder Bar Bridge

- Quick Turn Injector

- Ultra Bond 100 Resin

- Cordless 365nm UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method -Flex and Release, cure under pressure

NOTE: This Lab Report only is in pounds instead of Newtons.

New Glass Score = 101 lbs or 449 Newtons

Repair Test Score = 137 lbs or 609 Newtons = 136% of New Glass.

Conclusion - The Ultra Bond Wonder Bar Bridge Tool with 100 resin produces the strongest chip repair in the world at 136%of new laminated glass. This tool is able to easily inject resins 3-5 times thicker than what the others use. Thicker resins are stronger and more durable.

Click Here to see ROLAGS Long Crack Repair Test Reports and Scores.

#2 115%

Ultra Bond Wonder Bar Windshield Repair Kit

Test Components:

- Ultra Bond Wonder Bar Bridge

- Quick Turn Injector

- Ultra Bond 70 Resin

- Cordless UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method -Flex and Release, cure under pressure

New Glass Score = 623 Newtons

Repair Test Score = 719 Newtons or 118% of New Laminated Glass.

Conclusion - The Ultra Bond Wonder Bar Bridge Tool with 70 resin produces the strongest low viscosity chip repair. The O-ring sealed piston has 28 HGs of vacuum for removing air and degassing resin.

Click Here to see ROLAGS Long Crack Repair Test Reports and Scores.

#3 108%

Ultra Bond Wonder Bar Windshield Repair Kit

Test Components:

- Ultra Bond Wonder Bar Bridge

- Quick Turn Injector

- Ultra Bond 40 Resin

- Cordless UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method -Flex and Release, cure under pressure

New Glass Score = 664 Newtons, SD- 168

Repair Test Score = 719 Newtons or 108% of New Laminated Glass.

Conclusion - The Ultra Bond Wonder Bar Bridge Tool with 40 resin produces the only lower end of low viscosity chip repair resins that is over 100% of new windshield glass. No resin lower than 40 cps will reach 100% restoration in any other tool.

Click Here to see ROLAGS Long Crack Repair Test Reports and Scores.

#4 100%

Ultra Bond Hybrid Windshield Repair Tool

Test Components:

- Ultra Bond Hybrid Windshield Repair Tool

- Ultra Bond 100 Resin

- Cordless UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, cure under pressure

New Glass Score = 553 Newtons

Repair Test Score = 553 Newtons or 100% of New Laminated Glass.

Comments - The New (2023) Ultra Bond Windshield Repair Tool with 100 resin scored 100% of new laminated glass strength. Note: this tool is one of its kind with both the grommet sleeve and a vacuum seal on the piston and a double cylinder chamber creating more vacuum and pressure than just the grommet seal type injectors. Vacuum improves wicking and pressure increases wetting. It also degasses the resin like an O-Ring sealed piston. Other tools with a grommet sleeve (Delta, Novus, Amazon and Walmart DIY Kits) have little to no vacuum, cannot degas the resin and one cylinder chamber.

#5 79%

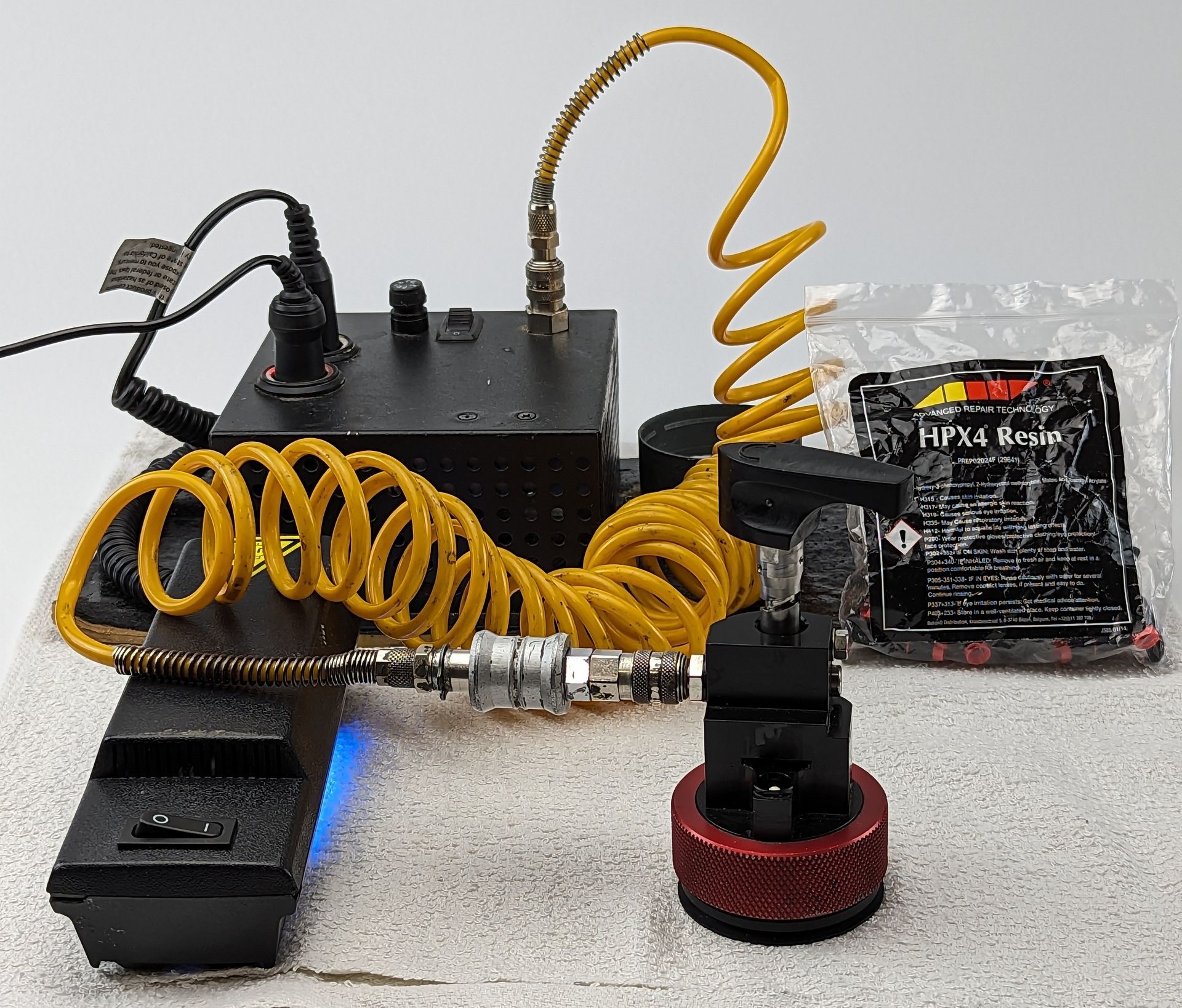

Glas Weld Eco Vac Tool Windshield Repair Kit

Test Components:

- Eco Vac Tool

- Glas Weld Gray Resin

- Cordless UV Fluorescent Cure Light

- Break Type - star/combination break

- Method - Vacuum and Pressure, cure under pressure

New Glass Score = 590 Newtons, SD- 59

Repair Test Score = 471 Newtons or 79% of New Laminated Glass.

Comments - The Glas Weld Eco Vac Windshield Repair Kit with Gray tinted resin scored 79% of new laminated glass strength. This previous Glas Weld tool cured with the pictured inexpensive fluorescent light scored much better than their current Zoom Tool cured their expensive LED Procure light. Inexpensive fluorescent lights as shown in the picture are more effective in a structural application; have lower standard deviation, are more consistent and need no secondary cure from sunlight.

#6 78%

Ultra Bond D-I-Y/Pro Windshield Repair Kit

Test Components:

- Ultra Bond Black Tripod DIY Tool

- Ultra Bond 45 Resin

- Cordless UV 365 nm Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, cure under pressure

New Glass Score = 590 Newtons, SD- 59

Repair Test Score = 462 Newtons or 78% of New Laminated Glass.

Conclusion - The Ultra Bond D-I-Y Windshield Repair Kit with 45 resin scored 78% of new laminated glass strength. This is the highest score of any do-it-yourself windshield repair kit on the market and is higher than most professional windshield repair kits. It can also be used as a professional chip repair kit.

#7 78%

Safelite's RAZ Tool Windshield Repair Kit

Test Components:

- Safelite RAZ Tool System

- HPX4 Resin

- UV 365 nm Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, no cure under pressure

New Glass Score = 513 Newtons

Repair Test Score = 398 Newtons or 78% of New Laminated Glass.

Conclusion - Safelite's advertisements and brochures sent to the insurance companies and others stated that they restore the structural integrity and are the strongest part of the windshield. They also advertise and told the insurance companies that they were 3 times stronger than the average brand in the United States. Those tests were not industry recognized lab tests for windshield repair systems. The industry developed ROLAGS test show that their advertising is false.

#8 67%

Delta B-150 Windshield Repair Kit

Test Components:

- Delta B-150 Tool

- Delta Magnibond 18cps Resin

- LED Cure

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, NO cure under pressure

New Glass Score = 428 Newtons, SD - 89

Repair Test Score = 287 Newtons or 67% of New Laminated Glass Strength

Conclusion - The Delta B-150 Windshield Repair Kit with Delta Magnibond 18 cps resin scored 67% of new laminated glass strength. This company states they do exhaustive testing but does not disclose any numbers. In the crack test with their Magnibond resin (see the above graph of an inferior repair) they had one of the lowest scores in the industry.

#9 65%

American Windshield Repair System's Kit

Test Components:

- American WRS Tool

- American Thin Resin

- Cordless UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, cure under pressure

New Glass Scores = 590 and 428 Newtons (multiple batch's of glass)

Repair Test Score = 65%, 56% and 80% = 65%

Conclusion - The American WRS Windshield Repair Kit with Thin Resin scored 65% of new laminated glass strength. See others for SD on the new glass.

#10 58%

Permatex D-I-Y Windshield Repair Kit

Test Components:

- Disc and syringe

- Permatex Resin

- Sunlight Cure

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure

New Glass Score = 590 Newtons, SD - 59

Repair Test Score = 58% of New Laminated Glass Strength

Conclusion - The Permatex D-I-Y Windshield Repair Kit scored 58% of new laminated glass strength in the break types required by the ROLAGS which is a star/combination break. This kit specifies that it is for bullseye breaks which are the round shaped breaks that were prevalent when windshields were much thicker prior to the first gas crunch in the 1970s after which the thickness of windshields were cut in half to reduce weight to improve gas mileage. This reduction in glass thickness was also the beginning of windshields becoming the number one insurance claim in the United States. The bullseye in modern windshield is rare because the glass layers are only 2 millimeters thick and break into a star/ combination break instead of a bullseye.

#11 57% - Only Because it was Repaired by a Professional.

Amazon and Amazon Remarketing Clickbait Sites

Test Components:

- Amazon's numerous sellers

- Exact Same: Tool, Resin, Instructions and Pictures in Every Kit

- Florescent 365 nm Cure

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, NO cure under pressure

New Glass Score = 571 Newtons, SD- 59

Repair Test Score = 263, 294 and 429 Newtons or average of 57% of New Glass Strength

Standard Deviation was extremely high.

COMMENTS: Two out of three of these repair samples needed to have legs (cracks) manually flexed, which is not taught in the instructions. This is what professionals know how to do. Two of these samples would of had a score of ZERO if it was not repaired by a professional for these tests. Google searches show remarketing scammers are being paid by Amazon using Amazon customer reviews by lay persons to rank the Best windshield repair kits, which is False Advertising. It has been ruled in Federal Court that, "customer reviews (for windshield repair) does not mean it is Safe or can pass the ROLAGS." Ultra Bond v Safelite. The windshield is a safety devise that involves 4 Federal Safety Standards and there is the ROLAGS ANSI approved Windshield Repair Standard. Amazon and Google should change their marketing and algorithms when it comes to critical safety devises that have Federal or ANSI approved Safety Standards.

Conclusion - The Amazon D-I-Y Windshield Repair Kits scored 57% of new laminated glass strength. This type of Do-It-Yourself Kit can be purchased in bulk for less than about two dollars each, which is why you see many sellers on Amazon and Amazon's Clickbait Scammers when you search for windshield repair kits.

#12 53%

Delta B-250 Windshield Repair Kit

Test Components:

- Delta B-250 Tool

- Delta Magnibond 18cps Resin

- Delta LED Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, NO cure under pressure

New Glass Score = 590 and 547 Newtons (multiple batches' of glass)

Test Score = (275, 330) and 330 Newtons or 53% of New Glass.

Comments - The Delta B-250 Windshield Repair Kit with Magnibond 18cps Resin and their high intensity LED curing light scored 53% of new laminated glass strength. Delta for over 30 years is the ONLY Professional Manufacturer that does NOT recommend curing under pressure even though their resin manufacturer recommends it. In my opinion this is puzzling to me as pressure in any low viscosity adhesive application increases the bond, which is why all the others recommend it. It is a fundamental fact of adhesives. They say they do exhaustive testing but disclose no numbers. They must not have compared curing under pressure versus not curing under pressure because we did and curing under pressure with their tool and their resin was 16 points higher or 20% stronger. You should request a 3-Point Bend Lab Test report with NUMBERS if you buy from them. SD on the new glass was low at 59 and 21.

#13 50%

Clear Shield Windshield Repair Kit

Test Components:

- Clear Shield Tool

- Clear Shield Thin Resin

- Cordless UV Fluorescent Cure Light

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, cure under pressure

New Glass Score = 590 Newtons, SD - 59

Repair Test Score = 297 Newtons or 50% of New Glass Strength

Conclusion - The Clear Shield Windshield Repair Kit with Thin Resin scored 50% of new laminated glass strength. This is another one that states they do exhaustive testing but discloses nothing.

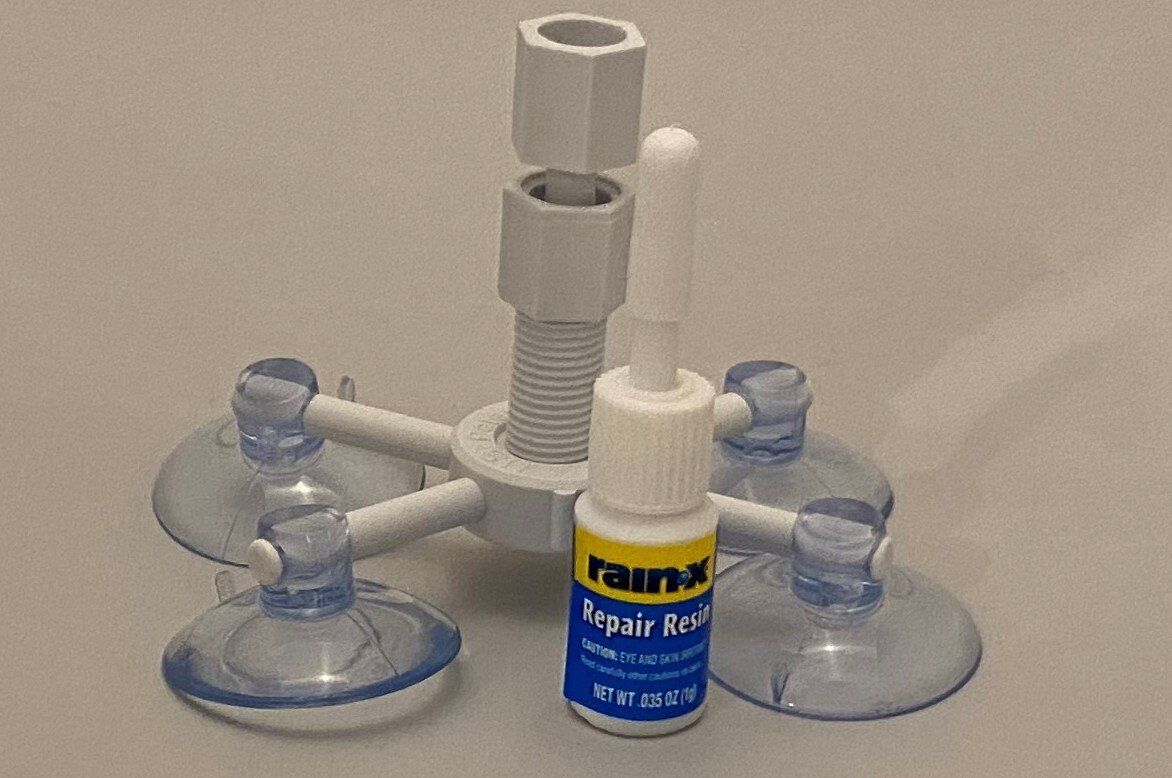

#14 45%

Test Components:

- Rain X Tool

- Rain X Resin

- Sunlight cure

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, NO cure under pressure

New Glass Score = 590 Newtons, SD- 59

Repair Test Score = 263 Newtons or 45% of New Glass Strength

Conclusion - The RainX D-I-Y Windshield Repair Kit scored 45% of new laminated glass strength. This type of Do-It-Yourself Kit can be purchased in bulk from Taiwan for less than about three dollars each.

#15 Undetermined

Glas Weld Zoom Windshield Repair Kit

Test Components:

- Glas Weld Zoom Tool

- Gray Tinted Resin

- LED ProCure+ curing light ($280.00)

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, cure under pressure

New Glass Score = 547 Newtons, SD- 21

Repair Test Score = 208 Newtons or 38%, SD- 105

Comments - Glas Weld stated at a ROLAGS meeting in 2023 that they have done these ROLAGS Lab Tests. Once they disclose those results, we will put them up here. You should ask for the report.

This was the most problematic system tested. Had to be retested multiple times due to cracking-out during thermal cycling and then a process of elimination to figure out the problem(s). Their previous Eco Vac tool scored much better; the difference being a threaded mounting system versus a click-in mounting system and a fluorescent cure light. Compression on the glass with the Zoom Tool click-in mounting is weak and not controlled by threads (all other professional systems and most D-I-Y Kits use threads). YouTube videos by users and Glas Weld shows it leaks, wobbles in the tripod and are always having to manually flex legs with a probe to get them to fill even when using a water thin 18 cps resin. Threaded mounting offers feel and precise control of the pressure/compression on the glass and the seal. This click-in is by manually pushing down on the injector

????

This can result in an underfill instead of a compete fill if you do not push down hard enough, which you may have a tendency to do to prevent spreading the break, especially on a hot windshield. If the initial push to seal the injector seal on the glass is not enough and it leaks resin, as it usually does on the YouTube videos of this tool, instead of a slight turn with a threaded mount you have to push down on the injector . The

Procur+ LED light seemed to be not producing a proper cure either. LED Cure lights do not give off uniform UV Energy which creates tension/weak-spots in the cured resin. LED cures have the lowest lab test scores and have the highest standard deviation because each LED Bulb gives off a different intensity and they diminish over time each at a different rate, which means a lack of consistency. We compared the Procur+ versus a $9.95 Fluorescent using the same resin in an Ultra Bond tool. The 365 nm fluorescent scored 89%; the Procure LED scored 57%. In my opinion it is hit or miss with the click-in mounting and the Procur+ Light.

#16 34%

3M D-I-Y Windshield Repair Kit

Test Components:

- 3M bridge Tool

- 3M resin

- Sunlight Cure

- Break Type - Star-Break/Combination Break

- Method - Vacuum and Pressure, no cure under pressure

New Glass Score = 590 Newtons, SD -59

Repair Test Score = 202 Newtons or 34% of New Glass Strength.

Conclusion - The 3M Do-It-Yourself Windshield Repair Kit scored 34% of new laminated glass strength. In my opinion, this kit would have done much better with maybe a different resin AND or cured under pressure.

HOW THE TESTS WORKS

Laminated glass samples are cut into 12" x 6" - 12" X 9" samples. Each batch of glass has three samples tested as new (undamaged) glass to get a mean score for the repaired samples to compare to. Each batch of new glass and each size will have a different score to compare to. Each repair test is of three samples where a real-world star-break or combination break is made with a spring loaded center punch in the center of the glass, in the crack test the samples are cracked edge to edge with the help of a glass cutter, then repaired and cured. The samples are then placed in a freezer, then an oven for three rounds called the Resistance to Thermal Cycling Test. After the exposure test the samples are tested by placing the repair side down on the 3-Point Bend Machine which will put the repaired side into tension and cause this side to break first if there is a weakness. The load is applied at a rate of 5mm per minute. When the repair gives or that side of the glass breaks a dip appears in the graph and that is the repair's score

- All repairs were exposed to Thermal Cycling before the mechanical strength test. Thermal cycling simulates what an un-garaged vehicle in a four season climate will be exposed to. This was 12 hours in a freezer at -10 f; then two hours in an oven (NOT PREHEATED) at 170 f for three rounds.

- All repairs were cured with the manufacturers curing light and method of cure except where noted.

- All repairs were video taped and photographed before and after thermal cycling.

- Standard Deviation (SD)is the measure of how dispersed the data is in relation to the mean. A high Standard Deviation of the new glass itself can effect the scores. For example the glass could fail but not the repair at a lower point than the mean. Another example is when two scores are almost identical but one of the three is way off the other two. High SD on repair tests can mean a lack of consistency if the SD on the glass is low and the SD on the repair is high.

- Note - no matter how much stuff is in a windshield repair kit there are two major physical components that differentiate one system from another. It is those two components that actually do the repair and that is the tool and the resin.